Should you get your PCBs cleaned after assembly?

Here's What You Need to Know

At FlashPCB, we’re committed to delivering high-quality assemblies with the reliability and consistency our customers expect. One of the most common questions we get after a build is: “Do you clean the boards?”

The answer: it depends.

Why Clean PCBs at All?

PCB cleaning is used to remove flux residues and other contaminants that remain on the board after soldering. For water-soluble flux , these residues can lead to issues like corrosion, dendritic growth, or electrical leakage—particularly in high-voltage applications.

For assemblies built to IPC Class 2 standards (the most common class for industrial and commercial electronics—and the standard FlashPCB builds to), cleaning can be performed when specified, but it is not required if a no-clean solder paste is used.

Our Cleaning Process

For boards that require post-assembly cleaning, we use an Aqua Rose closed-loop cleaning system with Viigon NX 728 chemistry from Zestron . This professional-grade setup uses deionized (DI) water and a specialized cleaning agent to remove ionic and non-ionic contaminants.

The closed-loop system filters and reuses water, making it both environmentally responsible and highly effective. Viigon NX 728 is industry-proven , low VOC , eco-friendly , and its pH-neutral formulation is compatible with sensitive materials like copper, brass, and aluminum.

However, cleaning does take time. The full cleaning cycle takes about 2.5 hours , but because boards must be thoroughly dried, it typically adds one day and some additional cost to the total assembly process.

When Cleaning Is Not Performed

While our process is thorough and safe for most components, not all boards can or should be cleaned:

-

Under-component cleaning is limited: Some components—like BGAs, LGAs, and other bottom-terminated devices—cannot be effectively cleaned underneath. Even the best aqueous wash systems can’t reliably reach beneath tightly packed packages, meaning some flux residue may remain. In these cases, using water-soluble flux without cleaning will likely lead to corrosion and dendrite growth .

-

Component sensitivity: Some parts cannot be exposed to water at all. Many chips have open ports, exposed sensors, or are not sealed , and they may be damaged during washing.

For example, most air pressure, humidity, and CO₂ sensors cannot be washed . -

Specialty components: Items like potted power supplies may not be washable or may require explicit drying procedures , as moisture can seep in around terminations and become trapped.

-

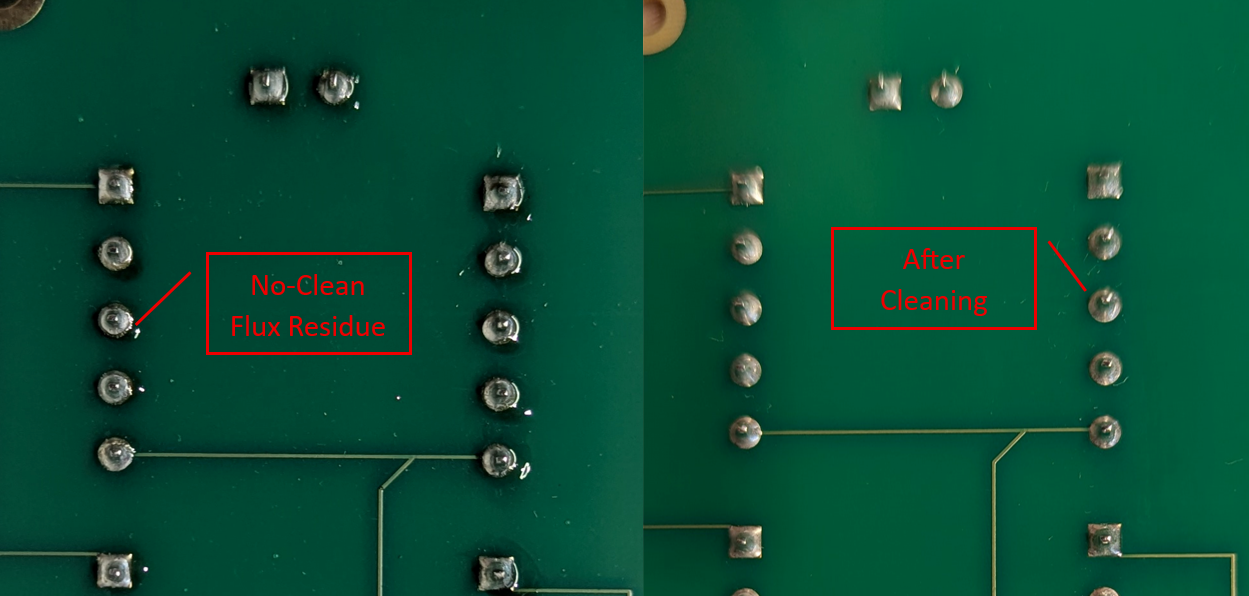

No-clean solder paste: Boards assembled with no-clean solder paste —our default procedure— do not require cleaning . This flux leaves minimal residue that is safe to remain on the board. We typically don’t clean these assemblies unless you specifically request it.

When Cleaning Is Required

If your assembly uses a water-soluble solder paste , cleaning is not optional . The flux is highly conductive and corrosive if left on the board.

Cleaning may also be required in other scenarios:

- Before conformal coating , as flux residues can interfere with adhesion.

- For aerospace, medical, or IPC Class 3 assemblies , where maximum reliability is critical.

- When customer specifications explicitly require it.

Additionally, some customers request cleaning for non-technical reasons . While Class 2 boards assembled with no-clean paste will not have sticky or corrosive residues, the flux may still be visible . In these cases, cleaning improves the visual quality of the assembly and may enhance the perceived value of the final product.

Should You Request Cleaning?

For most general-use applications, no-clean solder paste without cleaning is perfectly acceptable —and it's the most cost- and time-efficient option.

But if your application involves:

- High voltage

- Harsh environments

- Conformal coating

- Or you simply want a super clean-looking board ...

...then yes, you should consider cleaning.

Final Thoughts

We’re happy to clean your boards when needed, but it’s important to understand how it impacts time, cost, and component compatibility . At FlashPCB, we’ll always work with you to understand your requirements—and if you’re not sure whether to clean or not, just ask.

Newsletter

For more information sign up at here.